Computed Tomography Scanning Services for Manufacturing Optimisation

CT scan services by ProCon X-Ray

Send us a part that you would like to have scanned, and we provide you with a detailed report to assist in refining your design and manufacturing process.

How the Process Works

After you have contacted us to express your interest, we consult with you to discuss the item that you would like to have investigated.

We discuss the material of the sample, the purpose of the investigation as well as the specifics of what you'd like to find out through the use of a CT scan.

We then perform the scan, evaluate the resulting images and compile a detailed report in which the images are explained and contextualised.

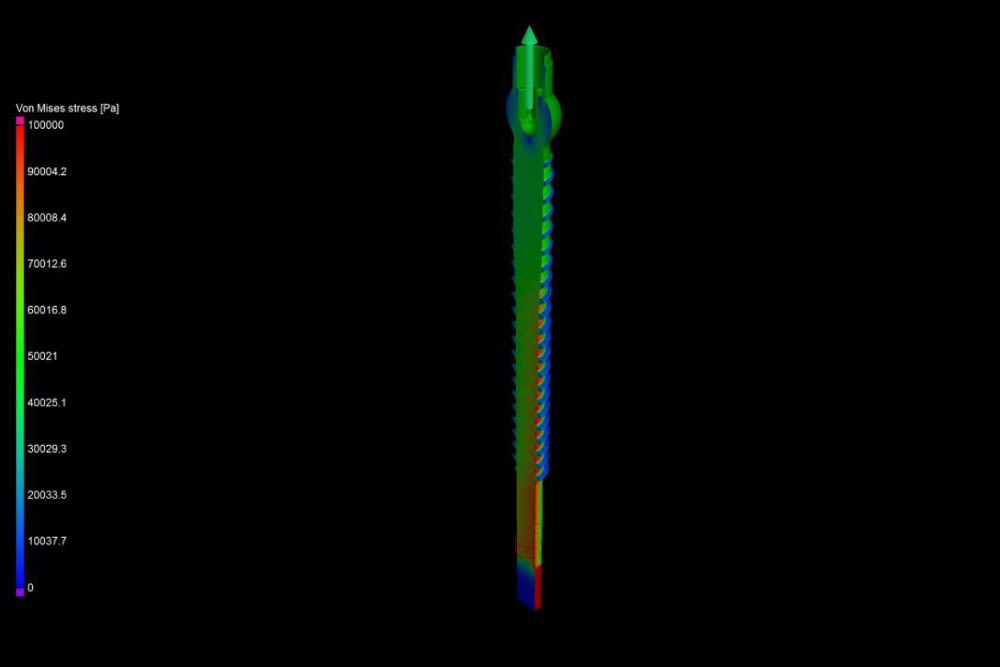

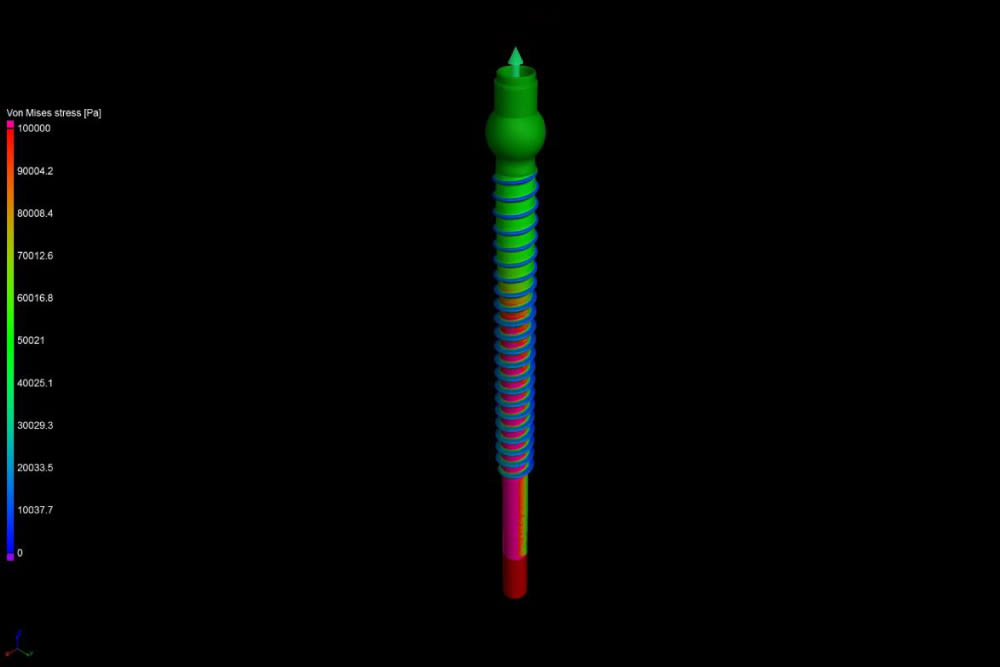

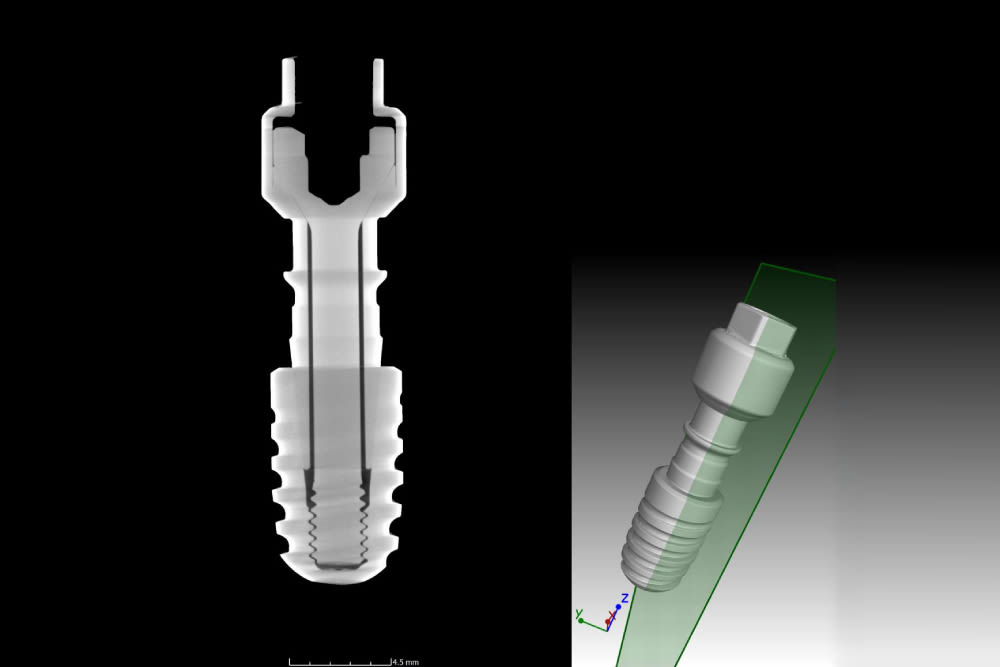

Stress Test Before Mass Production

CT scans can be used to determine the quality and durability of parts before significant investments are made into large-scale manufacturing.

When parts are required to meet strict quality standards in order to be certified by a laboratory, it makes sense to perform tests and create accurate simulations to determine whether a part would pass costly certification processes.

This image is an example of a screw where a stress test was simulated to determine potential weaknesses in the material.

Get in Touch with us

Want to find out more about a CT system for your organisation or institution?

Contact us.

Improve your Process and Product

Our CT scan service can assist in improving quality control and manufacturing processes.

By evaluating and assessing a part while still in the design, development and prototype phases, the overall quality of the manufacturing process — as well as the end product — can be significantly improved.

In industries where the safety of manufactured parts is critical in order to meet exacting quality standards, refining the design and prototype before large-scale manufacturing commences can save considerable time and money.

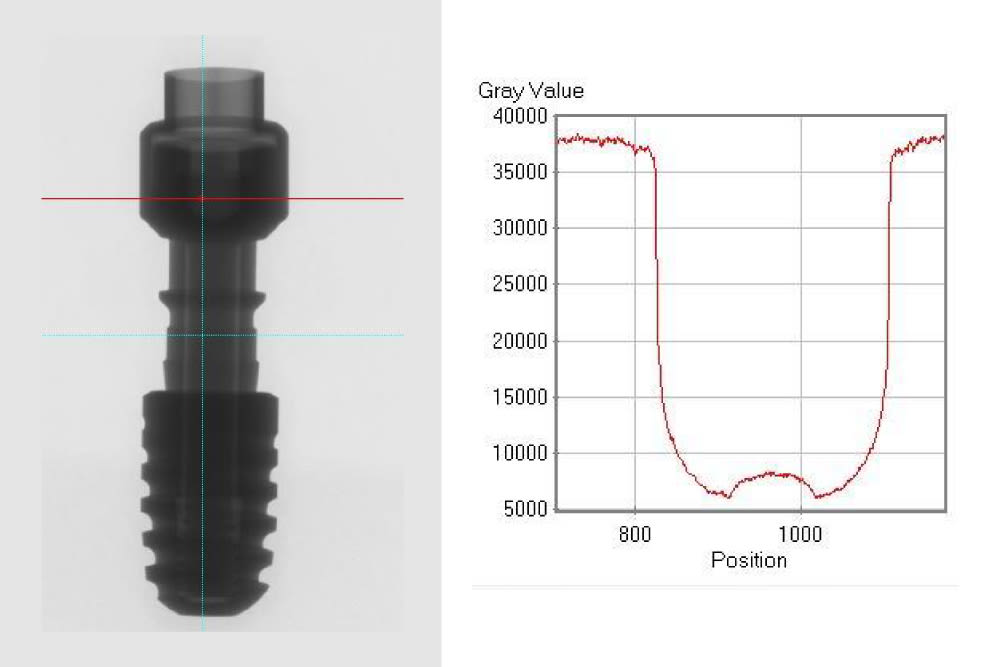

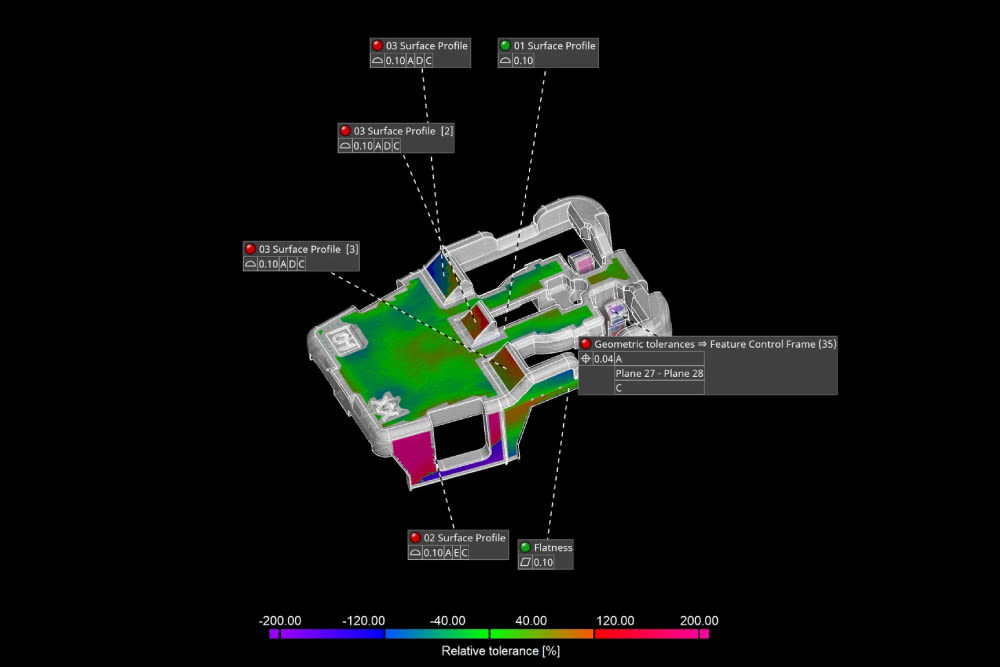

Dimensional 3D measurement technology

Dimensional 3D measurement technology offers the possibility of fast, single-point-based distance and angle analyses. This means that all shape and position tolerances can be evaluated.

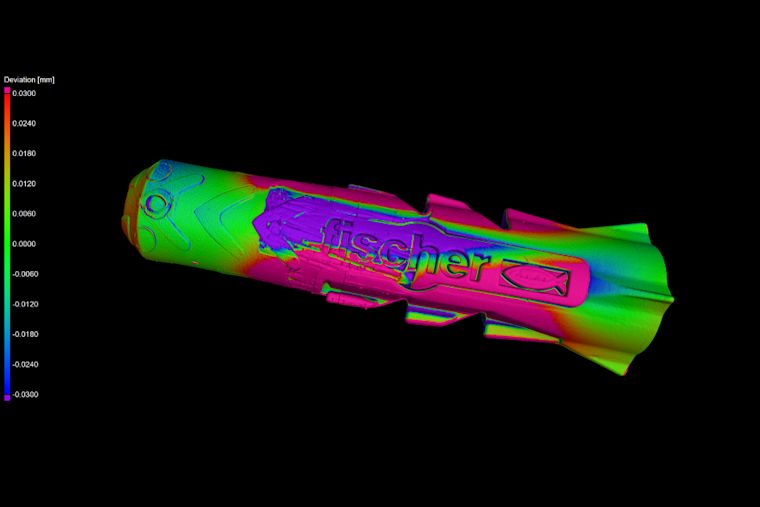

Surface analyses

Target/actual comparison: Color-coded comparisons between all data types provide easy-to-understand, visual information about deviations.

Wall thickness analysis

Analysis of the wall thickness of a part can be performed. We have the ability to create a direction-based assessment for cubic components or a sphere-based assessment for complex, organic geometries.

Confidentiality is guaranteed

Your test samples are treated with the strictest confidentiality.

We understand that trade secrets are to remain just that, and when required, we sign a non-disclosure agreement to keep both the sample and the test results confidential.

About the Company

ProCon X-Ray was founded in 2003 by Joachim Gudat. We started with 1 person and a vision, and are now a team of passionate engineers and salespeople all driven by one mission to help our clients explore new possibilities.

AboutWorking with companies to explore the future

We count the following companies among our successful partnerships.

Together with you, we look forward to working on further projects that explore new capabilities in the field.

This is your invitation to expose the unexpected with us.

Get in Touch with us

Want to find out more about a CT system for your organisation or institution?

Contact us.