CT-ALPHA nanotube

CT-system for resolutions down to 150 nm

The CT-ALPHA nanotube provides a unique solution for high-resolution measurements far ahead of established industrial micro CT scanners by applying the latest developments from X-ray research.

- Min. voxel sampling 50 nm

- Spatial resolution of 150 nm

- Photon counting detector

- Variable field of view

- Automatic alignment

- State-of-the-art reconstruction

Get in Touch with us

Want to find out more about a CT system for your organisation or institution?

Contact us.

Easy-to-Handle, Forward-Thinking Nano CT

The system combines the latest state-of-the-art components for highest resolution. Our experience in both hardware and software design enables us to perfectly adapt systems to your individual needs. Besides using only high-precision components, we also develop state-of-the-art reconstruction algorithms.

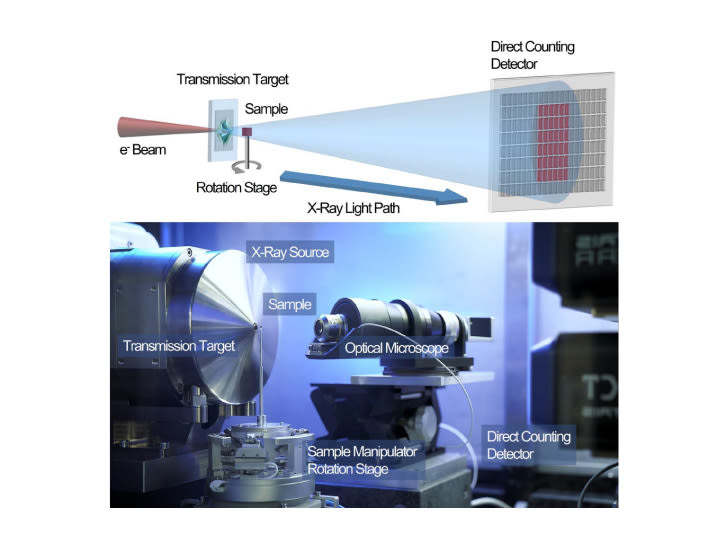

One main component of the system is Excillum’s high performance X‑ray source NanoTube N3, an up to 160 kV X‑ray tube with latest tungsten-diamond transmission target technology, automatic e‑beam focusing and astigmatism correction, ensuring that the smallest possible, truly round X‑ray spot is achieved.

The second main component is the photon counting X‑ray detector from DECTRIS. This detector enables an optimum signal-to-noise ratio due to zero readout noise and zero dark current. Moreover, dual energy discrimination enables digital spectrum adjustment.

Two separate manipulation systems allow a very precise detector and sample positioning. A high-precision air bearing rotary stage delivers a well-defined sample rotation, mounted on top of a linear position system with 3 degrees of freedom (DOFs). A separate manipulation (2 DOFs) system on top of the rotation stage is installed for automatically adjusting the sample position in the center of the rotation.

Specifications

Min. voxel sampling | 50 nm |

Max. geometric magnification | Up to 1,500 x for CT |

Photon-counting detector | Zero dark current |

Active area | 2,000 x 500 pixel @ 75 µm pixel size |

High efficiency even on low energies | For low contrast samples |

Variable field of view | 100 µm - 10 mm |

Spatial resolution | down to 150 nm |

Max. voltage | up to 160 kV |

Axis system | 12-axes manipulator |

Axis resolution | < 100 nm |

Automatic alignment | Easy-to-use workflow |

State-of-the-art reconstruction | Advanced algorithm |

Compact design | Small footprint of 2.0 m x 1.0 m |

Easy to Use

Scanning in nanometer resolution has never been easier.

The control software supports the user in all matters.

A separate manipulation (2 DOFs) system on top of the high-precision air bearing rotation stage is installed for adjusting the sample position in the center of the rotation by an automated routine.

From setting the scan parameters to reconstructing the volume, the user is guided by an easy and cleaned-up graphical user interface.

High Stability: The Prerequisite for Outstanding Resolution

For highest resolution with up to 150 nm, typical measurement times are 4 – 8 hours. Lower resolutions for this instrument, which is still at the limit of others, can be done in 1 – 2 hours.

Modern laboratory technology available for industrial applications

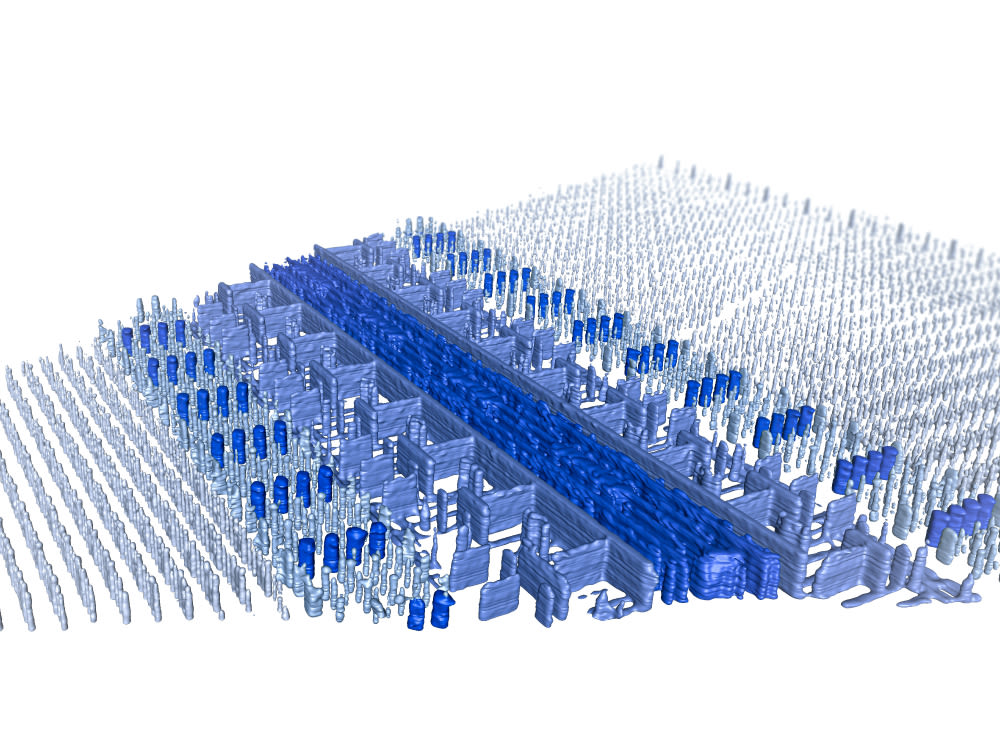

The functional features of novel material systems are often based on their complex inner structures, which are not accessible by established non-destructive analysis methods.

The fabrication of microelectronics and micromechanics becomes more and more complex, packed and 3D. After decades of successful miniaturization, industry now produces structures too small for established process control, hindering further improvements. Moreover, biological investigations would require more detailed 3D information of hidden inner structures in order to understand the morphology of various organisms, but such samples often provide too low material contrast.

Phase Contrast

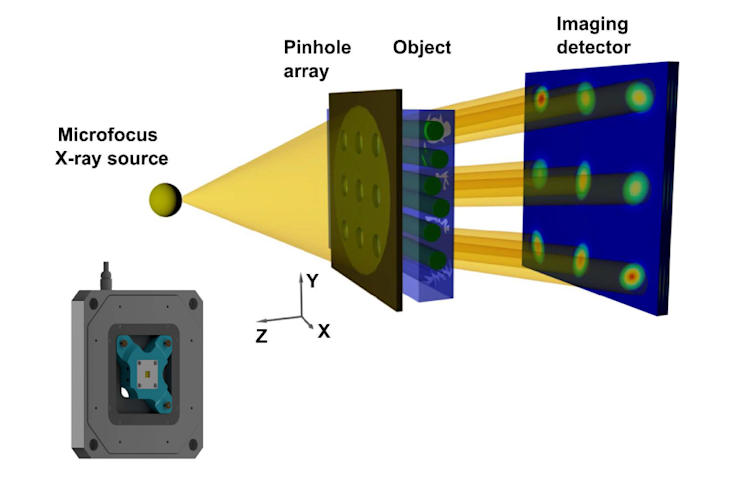

Our newly developed phase contrast add-on brings cutting-edge X-ray imaging to your CT system with unmatched simplicity and flexibility.

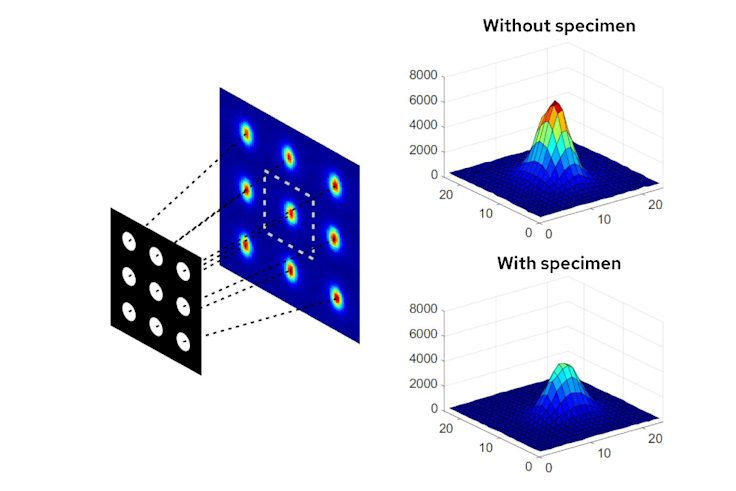

Using a specially designed pinhole array, it generates multiple fine, parallel X-ray beams that pass through the specimen. In a single scan, it captures absorption, phase contrast, and dark-field scattering – revealing structural details invisible to conventional absorption-based X-ray imaging.

Fundamental Idea

Your benefits at a glance

Easy integration: Simply mount the add-on in front of the detector — no major system modifications required.

New contrast modes: Visualise structures and features that remain hidden with traditional X-ray contrast.

Flexible application: Suitable for a wide range of materials, from lightweight composites like CFRP to biological samples.

Fast data acquisition: Multi-beam technology dramatically reduces scan times.

Comprehensive analysis: Absorption, phase shift, and scattering — all in one scan.

No rotation required: Scattering is recorded in all directions simultaneously.

Whether for research, quality control, or development, this add-on expands your CT’s capabilities, enabling you to see more, understand more, and discover the invisible — all with a simple retrofit.

Contrast Mechanisms

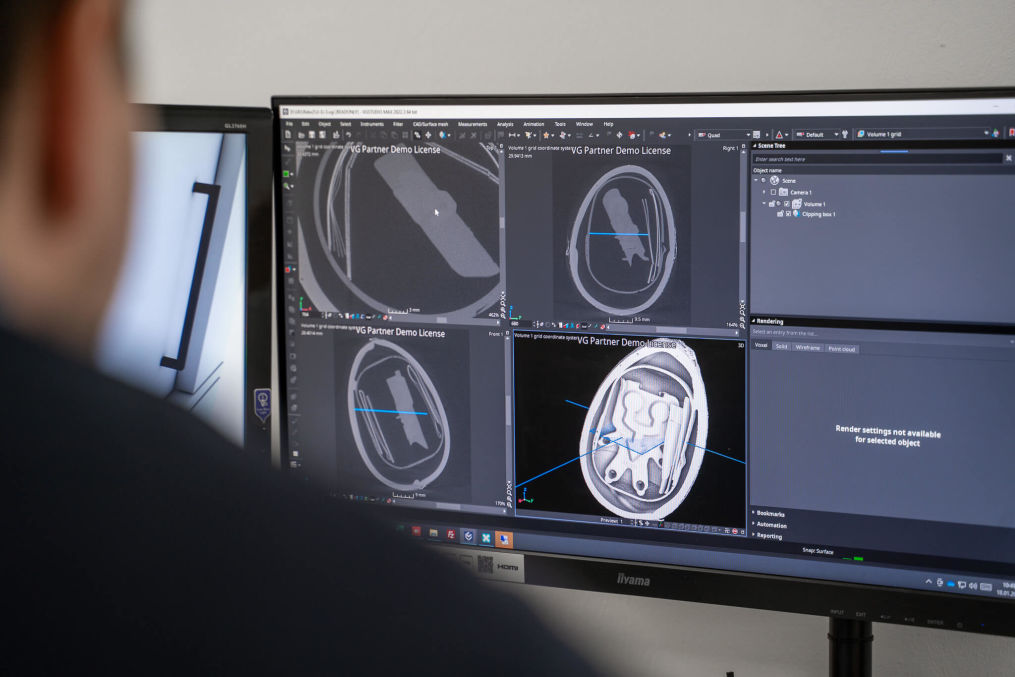

Hardware and Software Made for each other

The best hardware needs a great software program to run it and to help you get the best results out of your investment.

We create our own software, as well as recommend software from third parties based on your specific use case.

Learn more about software for your CT system here

Software

Get in Touch with us

Want to find out more about a CT system for your organisation or institution?

Contact us.