CT-COMPACT plus

CT-COMPACT plus, the most versatile benchtop system for 3D-CT requirements. “We enable the CT-COMPACT, performing as the most flexible micro CT system on a bench” Joachim Gudat, the founder and CEO of ProCon X‑Ray GmbH, says, during the companies 10th anniversary.

- Industrial X‑ray Computed Tomography (CT)

- 3D volume CT

- Non-destructive testing (NDT) – 2D and 3D

- Quality control independent of material

- Defect recognition (voids, cracks, …)

- Contactless metrology

- Numerous CT artefact corrections

- Easy operation

- Radiation safety better than 1 µSv/h

- Desktop system

Get in Touch with us

Want to find out more about a CT system for your organisation or institution?

Contact us.

Application Cases

Construction physics

Porosity analysis conducted on a piece of concrete. This sample of concrete has a diameter of 120 mm. A scan was conducted to analyse porosity, identifying cracks, holes, and air bubbles.

Geology

Our systems can be adapted to operate in extreme conditions. Long-term analysis of snow cores at the Canadian High Arctic Research Station at temperatures of -40°C. This system was adapted to insulate the X-ray source, and create a custom solution to ensure operation at extreme temperatures.

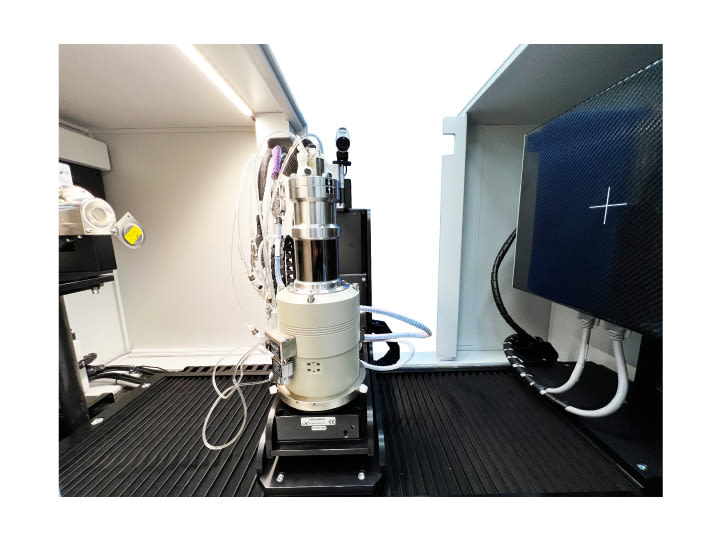

Versatility on a Benchtop

The space-saving CT-COMPACT plus can be equipped with micro-focus X‑ray tubes capable of operation up to 180 kV, depending on specific customer requirements. The focus-detector distance can be adjusted to optimize the contrast.

A range of flat panel detectors is available, enabling the highest magnification. Due to the horizontally oriented X‑ray beam, the CT scan remains uninfluenced by gravity.

The CT-COMPACT plus system is ideal for nondestructive testing, materials analysis, metrology and, rapid prototyping. Due to our cabinet temperature concept the CT-COMPACT plus holds the certificate of proven measurement uncertainty, by Q‑DAS.

Specifications

X-Ray source | 40 - 130 kV |

Detector | 7.5 Megapixel |

Highest spatial resolution | < 5 μm |

Smallest voxel size | < 1,2 μm |

Max. object dimensions | Ø 360 x H 600 mm |

Max. scan size | Ø 300 x H 330 mm |

Focus Detector Distance | 520 mm |

Focus Object Distance | 13 - 420 mm |

Number of axes | 5 |

System dimensions (L x W x H) | 1300 x 800 x 900 mm |

System weight | ~600 kg |

Phase Contrast

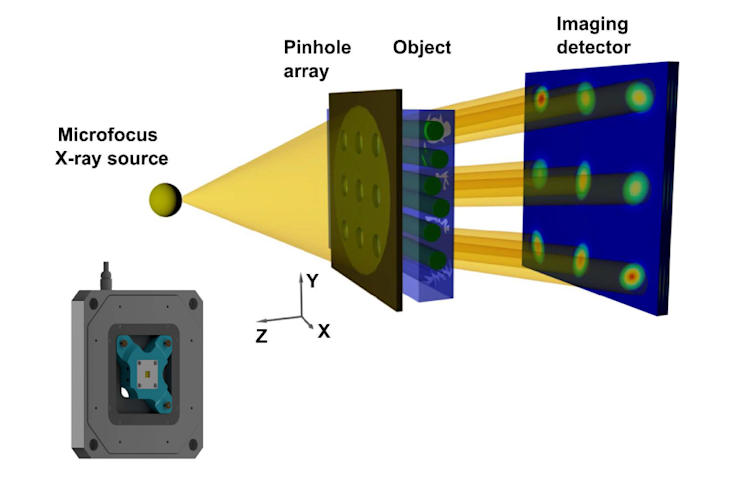

Our newly developed phase contrast add-on brings cutting-edge X-ray imaging to your CT system with unmatched simplicity and flexibility.

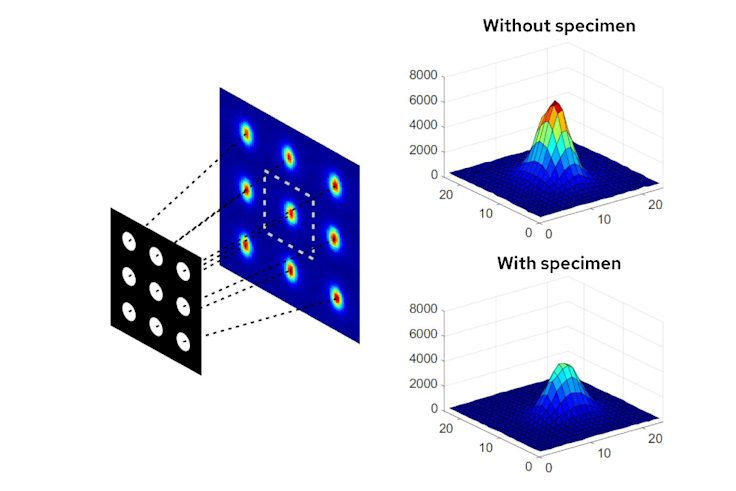

Using a specially designed pinhole array, it generates multiple fine, parallel X-ray beams that pass through the specimen. In a single scan, it captures absorption, phase contrast, and dark-field scattering – revealing structural details invisible to conventional absorption-based X-ray imaging.

Fundamental Idea

Your benefits at a glance

Easy integration: Simply mount the add-on in front of the detector — no major system modifications required.

New contrast modes: Visualise structures and features that remain hidden with traditional X-ray contrast.

Flexible application: Suitable for a wide range of materials, from lightweight composites like CFRP to biological samples.

Fast data acquisition: Multi-beam technology dramatically reduces scan times.

Comprehensive analysis: Absorption, phase shift, and scattering — all in one scan.

No rotation required: Scattering is recorded in all directions simultaneously.

Whether for research, quality control, or development, this add-on expands your CT’s capabilities, enabling you to see more, understand more, and discover the invisible — all with a simple retrofit.

Contrast Mechanisms

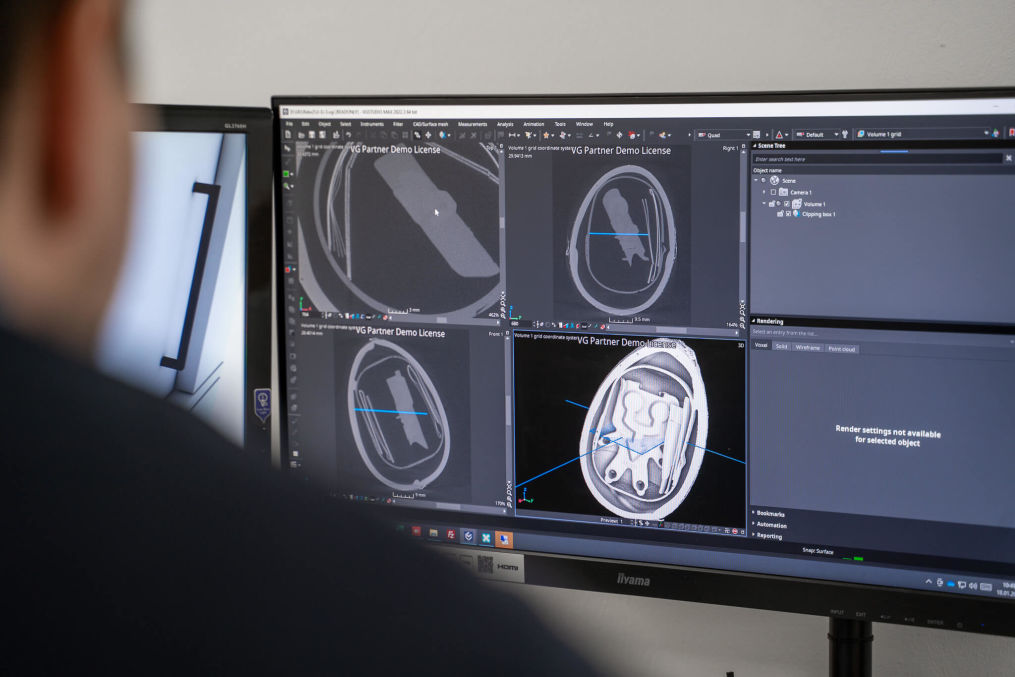

Hardware and Software Made for each other

The best hardware needs a great software program to run it and to help you get the best results out of your investment.

We create our own software, as well as recommend software from third parties based on your specific use case.

Learn more about software for your CT system here

Software

Get in Touch with us

Want to find out more about a CT system for your organisation or institution?

Contact us.